METAL SAFETY PROTECTORS

Although PTFE Spray Shields Are The Most Popular Shield Style, 316 Or 304 Stainless Steel Models Excel In Highly Aggressive And Demanding Applications, Including Concentrated Chemicals, Steam, Flammables, High Temperatures, And High Pressure Services.

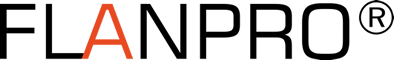

Metal security shields style I

FOR FLANGE GUARDS AND VALVE SHIELD

• Fabricated of 24- gauge, 316 or 304 stainless steel.

• Lockable, adjustable, quick latch fastener for easy installation.

• Stainless Steel netting absorbs and dissipates pressurized sprays by distributing it around the flange circumference.

• Available for all size and ratings of flanges, including square and oval shaped flanges.

• Available in widths of 2” and 2 ¾”.

• Maximum operating temperature of 2000° F/1093°C.

• Maximum operating pressure of 3000 psi.

• Optional safety locking pin.

• Optional 3/8″ or 1/2″ Diameter stainless steel drain nipple.

A) FLANGE GUARDS.

B) VALVE SHIELD.

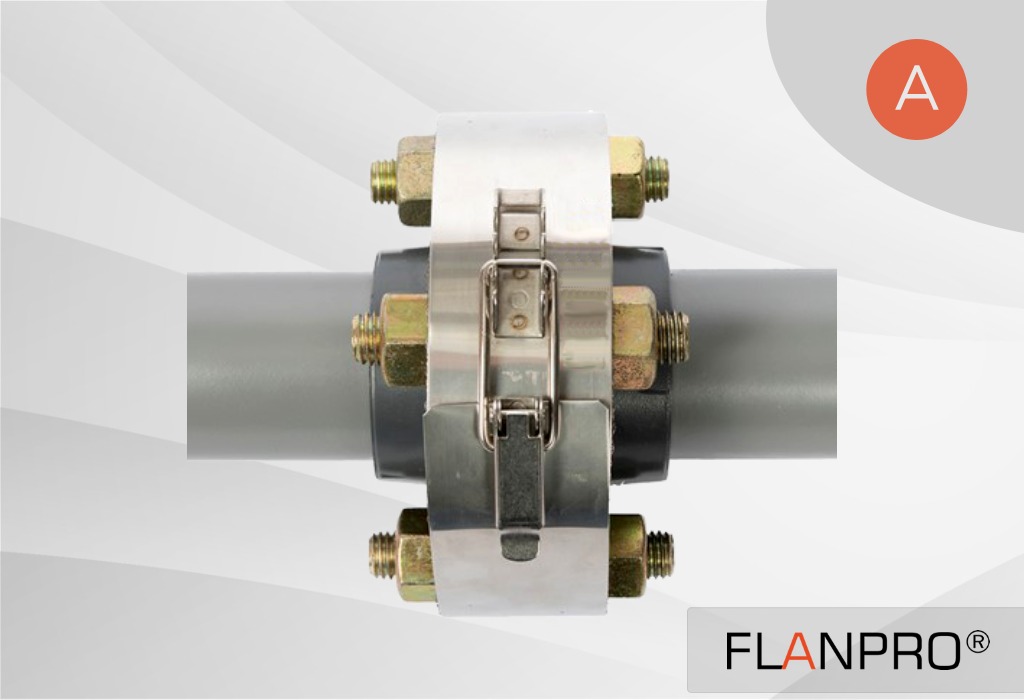

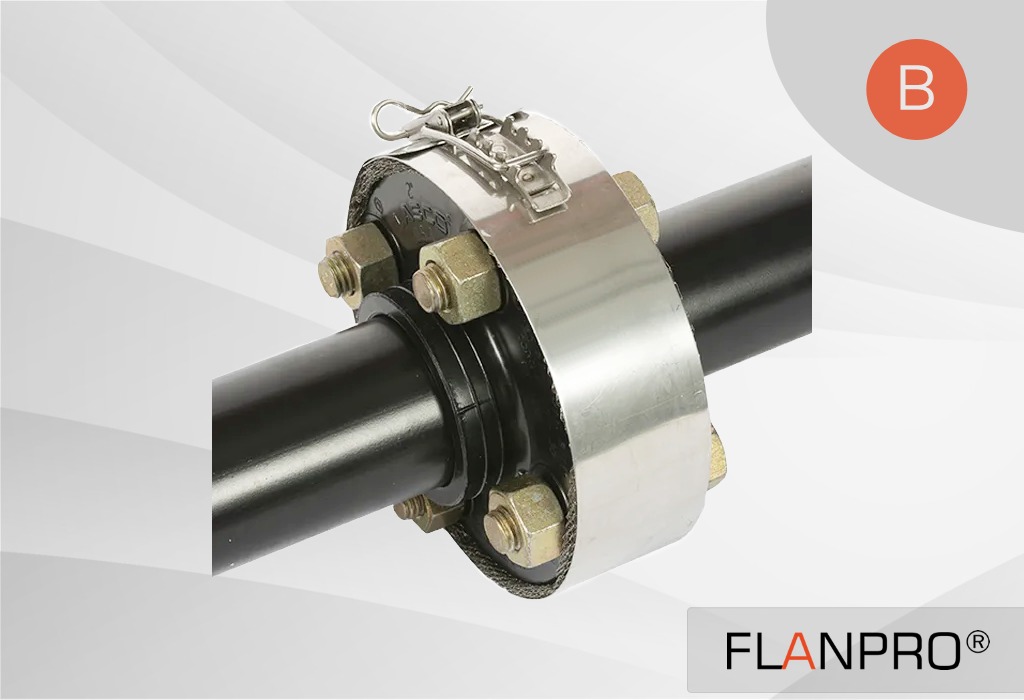

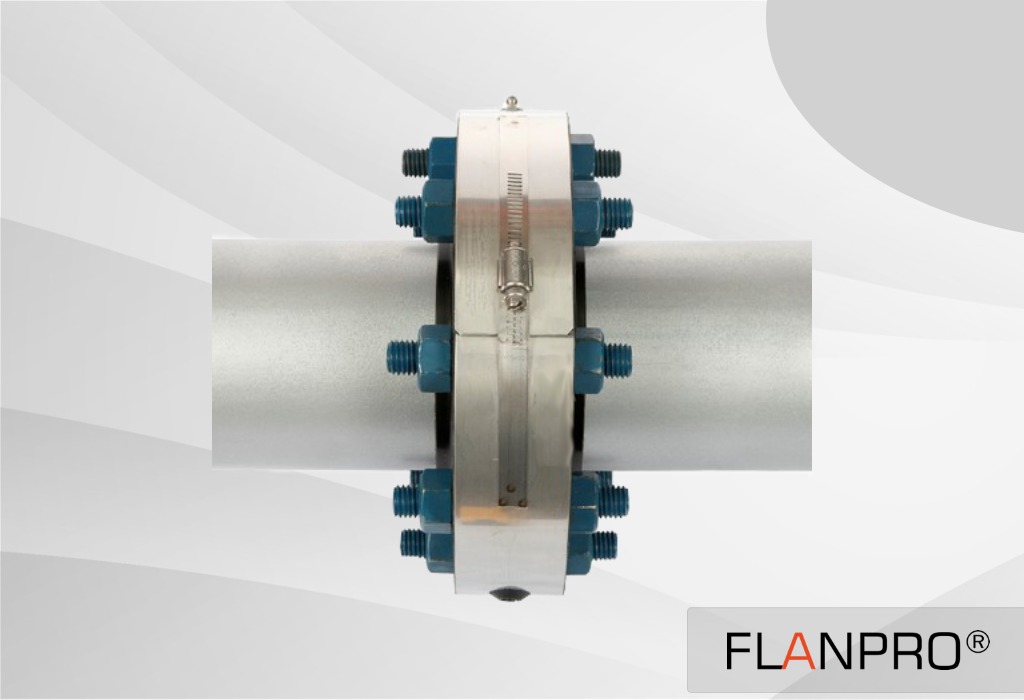

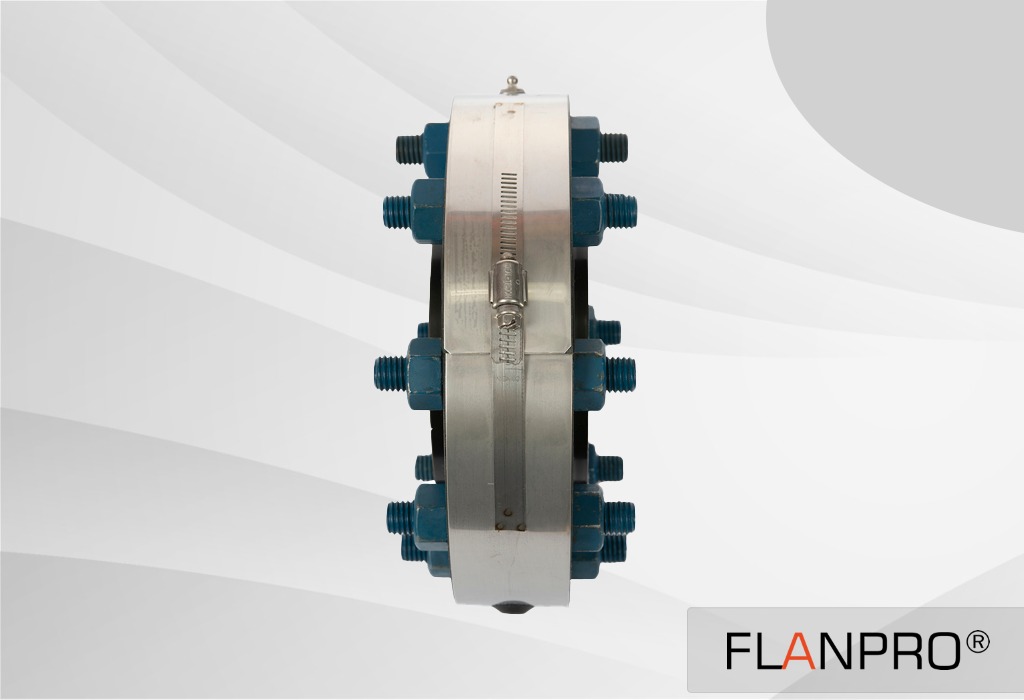

Metal security shields style II

Our 2nd most popular style of Metal Spray Shield is the well-known version: the wider, overlapping tabbed edges design that contains spacer rods which allow for spray redistribution.

FOR FLANGE GUARDS AND VALVE SHIELD

• Fabricated of 24- gauge, 304 or 316 stainless steel.

• Overlapping, slotted edges on sides to prevent lateral spray-outs.

• Stainless steel adjustable, hose clamp style fastener that requires a screwdriver or cordless drill for attachment.

• Stainless steel spacer rods.

• Available for all size and ratings of flanges.

• Maximum operating temperature of 2000° F/1093°C.

• Maximum operating pressure of 3000 psi.

• Optional 3/8″ or 1/2″ Diameter stainless steel drain nipple.

A) FLANGE GUARDS.

B) VALVE SHIELD.

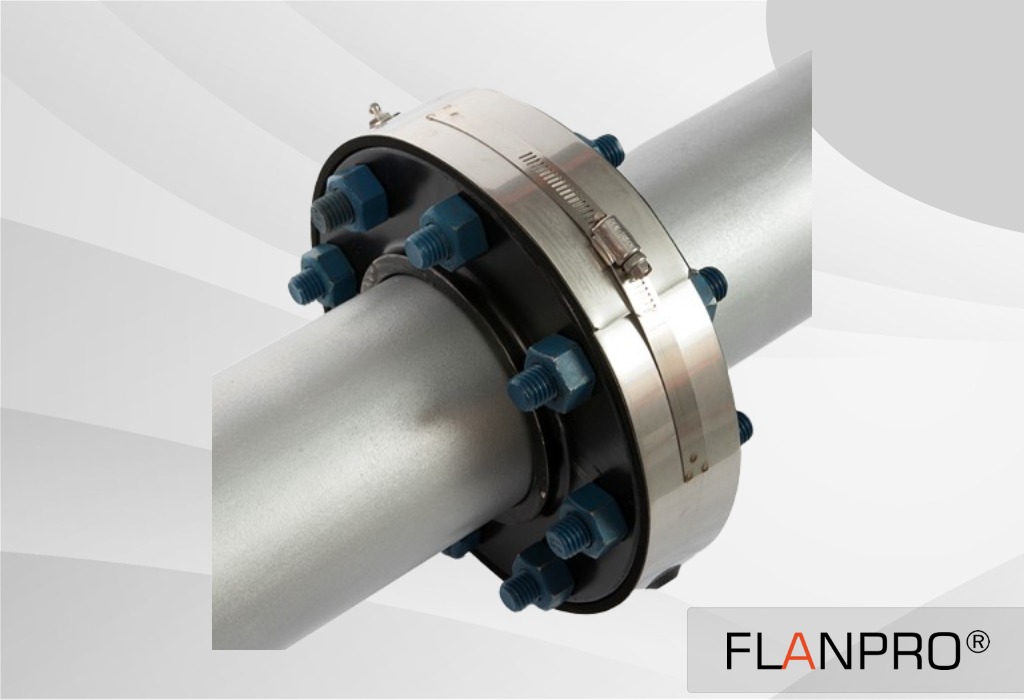

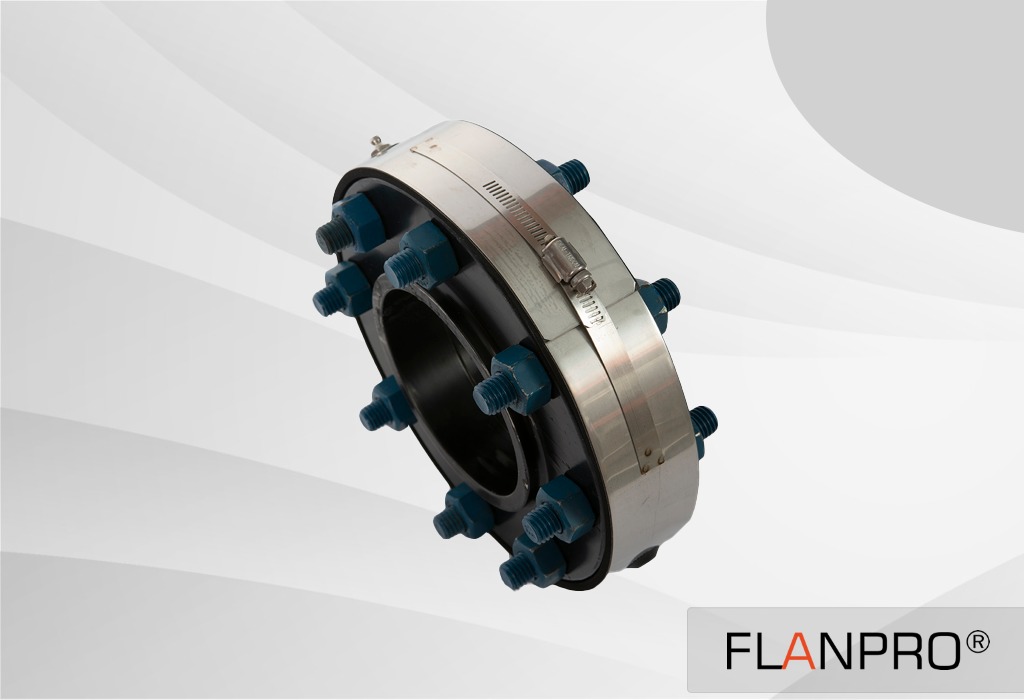

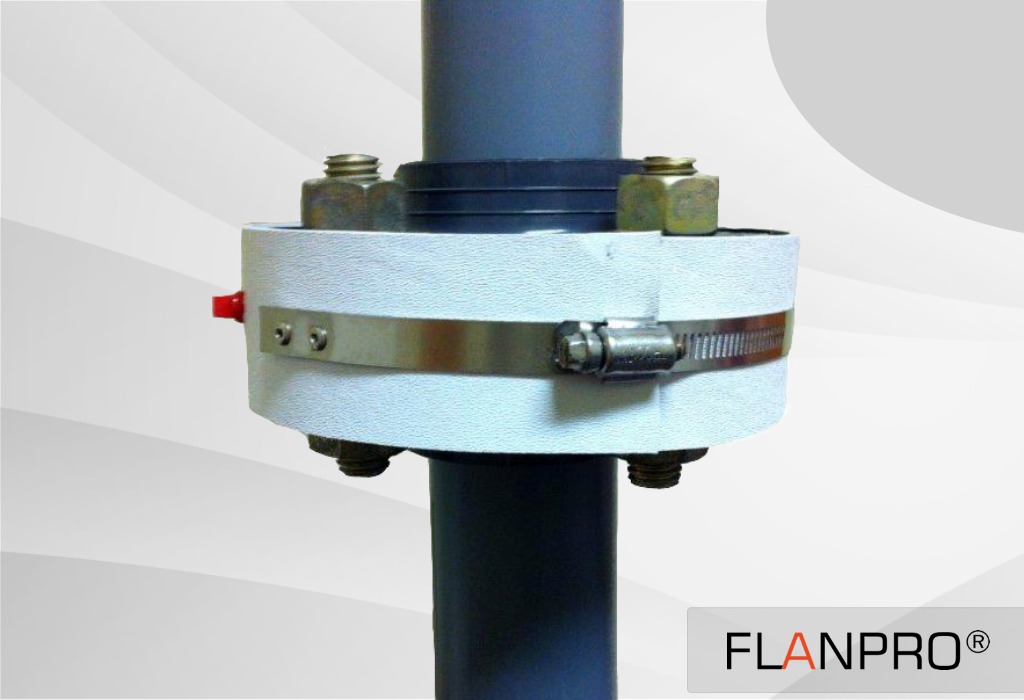

Flange band protectors

FOR FLANGE GUARDS.

• Constructed of 316 or 304 stainless steel, 316 stainless steel worm gear clamp, 316 stainless steel injection fitting with gasket liner of closed cell neoprene.

• Designed to cover flanges to protect flange faces, stud bolts, and gaskets from corrosion.

• Keeps moisture, chemicals, saltwater, acid rain etc. out.

• Quickly installed with a screwdriver.

• Available for all size flanges and custom engineered designs available per application.

• Available in 2″ and 3″ wide bands.

• Gasket liner of closed cell neoprene, maximum operating temperature of 250°F.

• Optional EPDM rubber gasket liner, maximum operating temperature of 270°F.

• Optional safety relief valve bleeds at 5- psi.

• Optional liner of PTFE or silicone for chemical and high temperature applications.

• Optional Kydex which is a High performance plastic/ Kydex is fire retardant, rigid, and has a high impact resistance.